|

| September 06, 2016 | Volume 12 Issue 33 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

NASA bets on bulk metallic glass gears for icy missions

NASA is developing technologies that will allow exploration of promising places in the solar system ranging from Mars to the icy moon of Jupiter, Europa. These locations have extreme environments that require hardware to withstand temperatures below -150 deg C. To put that in perspective, the lowest recorded temperature on any location on Earth's surface was -93.2 deg C (-135.8 deg F) on an Antarctic plateau.

More science can be accomplished on icy-body missions, like those to Europa, if spacecraft mechanisms can operate without power-consuming heaters. Researchers are developing unheated gearboxes to operate in these environments using custom bulk metallic glass (BMG) alloys invented at NASA specifically for this application. Gearboxes developed with the BMG technology must be capable of operating at surface temperatures of -173 deg C (-280 deg F).

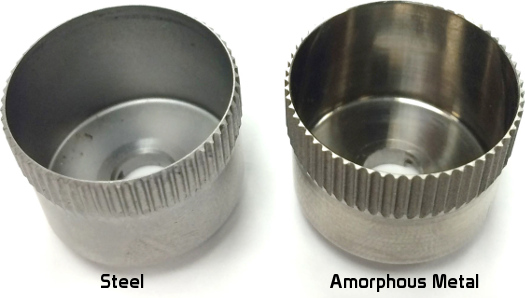

Amorphous metal can be cast into the final shape with no post-casting finishing steps required. Precise teeth shapes can be incorporated into the mold and replicated near perfectly into the castings. Certain alloys of amorphous metal (metallic glass) also have extremely good elastic, contact stress, and galling properties for this application.

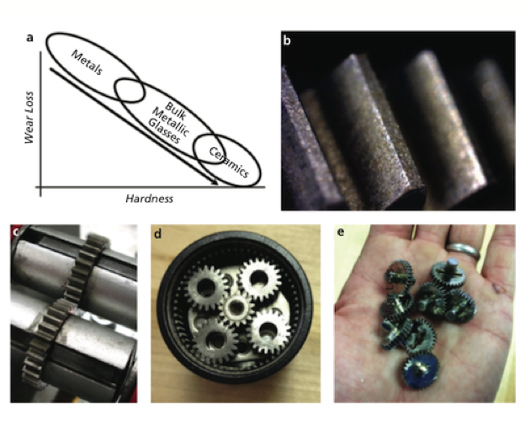

The composition and amorphous atomic structure of these new BMG alloys make them tougher than ceramics and twice as strong as steel, with better elastic properties than either. Combined with greater wear and corrosion resistance, these alloys are promising gearbox component materials.

The BMG Gears project within NASA's Space Technology's Game Changing Development Program (GCD) plans to demonstrate capabilities of custom BMG alloys in heaterless planetary and strain-wave gearbox configurations. Enabled by the materials working in extremely cold environments, mechanisms such as these could increase science return by reducing power consumption, mass, system complexity, and operational constraints. Applied to a Mars Curiosity-type rover, for example, this technology would enable nighttime operations during winter while saving 950 Watt hours per day; enough to run the remote-sensing mast while moving. The ~7 kg in ancillary electronics mass savings could allow another instrument to fly.

Currently, there are no materials specifications available that define acceptable ranges for the constituent components and minor elements in the BMGs that enable these gearboxes. NASA is working closely with industry to develop those specifications and mature a supply chain for the BMG alloys. An important benefit of using BMG alloys is that components can be directly molded from the material, and the supply chain for such gearbox components is also maturing.

Researchers want to determine operational boundaries and mechanism lifetime, because the ability of BMGs to perform at icy-body temperatures around -173 deg C has not yet been proven. Also, a heaterless planetary gearbox operating around -173 deg C has never before been produced, so there is a possibility that bearings, or other ancillary components not made from BMGs, may not have the necessary performance capability.

(a) Schematic showing the motivation for developing bulk metallic glass (BMG) gears. Crystalline metals tend to exhibit poor wear, while ceramics are brittle. BMGs offer wear resistance similar to ceramics but with up to two orders of magnitude higher toughness. (b) Micrograph showing teeth of a BMG gear. (c) Two BMG gears in a spur gear test; performances were shown to be up to three times better than the best steel alloys. (d) Cast BMG gears integrated into a working gearbox. (e) Cast BMG gears demonstrate ease of fabrication. [Images credit: NASA]

Some encouraging insights are being revealed early on. NASA developed a copper- and zirconium-based BMG alloy that was tested in a dry lubricated hybrid gearbox. Using a steel drive gear and BMG planet gears, this gearbox configuration ran 75 percent longer than a dry lubricated all-steel gearbox (14 million revolutions vs. 8 million revolutions). Furthermore, gear-on-gear testing has been performed using a drive gear and a brake gear to establish a contact stress between two geometrically similar, unlubricated gears of the same material composition. The test results indicate even greater potential for dry lubricated all-BMG gearboxes.

More than 3 million cycles were achieved at less than -100 deg C with a dry lubricated hybrid gearbox.

The BMG Gears project seeks to advance the technology for project infusion or a technology demonstration by maturing a cryo-capable BMG-based planetary gearbox with demonstrated performance exceeding current products. To do so, an understanding of the engineering challenges is necessary along with establishing design rules and guidelines for BMG alloy use in cryo-gearboxes. These technological advances mean a potential Europa Lander mission could include actuators or mechanisms without allocating power to heating gearboxes, thereby increasing the science return through increased mission lifetime or additional instrumentation.

See more examples of this project in a June 2016 PDF presentation by JPL's Dr. Scott Roberts by clicking on the title slide above.

The GCD Program investigates ideas and approaches that could solve significant technological problems and revolutionize future space endeavors. GCD projects develop technologies through component and subsystem testing on Earth to prepare them for future use in space. GCD is part of NASA's Space Technology Mission Directorate.

For more information about GCD, please visit http://gameon.nasa.gov/

Source: NASA Jet Propulsion Laboratory, California Institute of Technology

Published September 2016

Rate this article

View our terms of use and privacy policy